INFORMATION ABOUT MARGARINES:

Vegatble fats, margarines and their effects on health

Why vegetable margarines?

Vegetable margarines

play an important role in healthy human nutrition. Vegetable margarines

are produced from vegetable fats and oils like soybean, sunflowerseed,

cottonseed and palm oils. Thats why these fats are rich of unsaturated and

polyunsaturated fatty acids and contain 0 (zero) cholesterol. Unsaturated

fatty acids decrease bad cholesterol (LDL) and increase good (HDL) one and

thus helps you to avoid from coroner and cardiovascular diseases.

Saturated fats, like butter, increase cholesterol level in blood and

increase risk of cardiovascular disease. Beside unsaturated fatty acids

margarines are good source of vitamines A, D and E.

The role of margarines

in healthy nutrition

Most of margarine

consumers don’t understand the importance of margarines in human diet.

There are little amounts of saturated fat in it. Especially table

margarines are rich sources of unsaturated and polyunsaturated fatty acids.

The fats must be consumed accourding to daily diet in balance. In case of

getting 30% of energy from them it can be advised to take equal, 10% ratio

of saturated, unsaturated and polyunsaturated fats. The daily intake of

fats for adult man is 90 grams and for woman is minimum 65 grams. The

daily intake of fats is higher for children and they take 50% of daily

energy from such fatty foods like margarines and milk.

Margarines are rich

of unsaturated fats and vitamines. They are enriched with Vitamin A which

is growth factor and keeps eyes healthy. In case of vitamin D margarines

are more rich sources than butter. Vitamin D increases calcium ratio in

organism so it play an important role helath of teeth and bones

Coroner and

cardiovascular sourced deaths take one of first place between human deaths

in industrial and developing countries. WHO and other authorized

organizations advise intake of more unsaturated fats than saturated ones.

It is a fact that consumption of margarine instead of butter decreased

ratio of cardiovascular diseases in different countries. CANYAG

margarine will help you to prevent your heart from desease.

The daily margarine intake is also important for growing children.

Continuous intake of margarine helps them to take useful nutrients for

their growth. ERYAG pays an attention to children growth and enriches

CANYAG with vitamines and useful fats.

The importance

of vitamines of Canyag for health

The vitamin

ratios of foods is different and usually some of them may contain higher

amounts of vitamins and but lower one of others.

Margarines became a rich

source of vitamines since they are elements of diet. Producers must add

vitamins A and D to margarine accourding to Turkish Margarine Standard (TS

2812). The intake of vitamines soluble in oil with fat provides more

efficient usage of them in organism. The ratios of vitamines A and D in

Canyag is accourding to Turkish Margarine Standard.

MARGARINE

PRODUCTION TECHNOLOGY

Margarine is w/o emulsion type product and consist of vegetable fat, milk,

water and other additivities. It is possible to produce different purpose

margarin with various fat ratios (40%, 60%, 70% and 82%), fat compositions

and production ways.

Margarines are produced from 100% vegetable fats like sunflower, soybean,

cottonseed and palm oils.

The

production margarines begins from refining of fats.

REFINING

Refining is 3-stage operation which consist of

-Neutralization:

purification of fat from free fatty acids and other impurities

-Bleaching:

purification of fat from colour pigments

-Deodorization:

- purification of fat from indesirable falvours

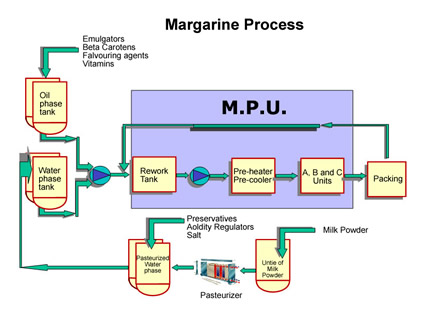

STAGES OF MARGARINE PRODUCTION

The

production of margarine is consist of stages written below:

-Preparation of fat and water phases

-Preparation of emulsion

-Cooling, crystallization and mixing

-Packing

1-

Preparation of fat and water phases

The water phase contains:

-salt

-milk, milk powder, whey powder

-Acidity regulator (citric acid)

-Antimicrobial additivities

The fat phase contains:

-emulgators

(monodiglycerides, lecitin)

-colourising agent (beta caroten)

-Flavouring agents

-Vitamines (A & D)

2- PREPARATION OF EMULSION

Fat

and water phases are mixing homogeneously accourding to desirable water

ratio.

3-

COOLING, CRYSTALLIZATION, KNEADING AND PACKING

Prepared w/o emulsion then goes to crystallization unit. This operaiton is

making in modern continuosly working crystallizators called margarin

production unit (MPU) or Votator.

When fats

are cooled by themselves then sandy, non homogeneous structures becomes

because of formation saturated triglycerides and non-homogeneous mass

formation following it. The aim of cooling and crystallization is to

obtain the fat with suitable appearance, stability and structure function.

So it is not enough just to cool the fat. During homogenization the water

phase is distributed in fat homogeneously and the size of its globullars

are reduced.

Despite at appearance of fats as homogeneous structure in microscopic

observation it can be seemed that there are cristalls penetrated to each

other and liquid fat between them. When the forced is applied to the fat

there are motion of crystalls to one another. Thus this mass had butter-like

behaviour.

To

obtain this specification:

-Solid and liquid phases must be distributed homogeneously in each other

to keep the mass stable.

-There

must be certain ratio between two phases

Fats are

being crystallized after cooling and this operation continues till the

final cristal form.

This is

carried out in MPU and these operations are irreversible. After final

crystallization if the fat is melted and crystallized the lower cristall

types are fomed. The crystal type determines specification of structure.

Cooling cylinders are used in emulsion cooling and crystallization and

amonium or freon are usedas coolers.

Hot

emulsion is pumped to cooling cylinders by high pressure pumps. Then the

emulsion is quickly cooled on cylinders surface and crystallizes.

Crystallized emulsion is scraped by high speed rotating knives. This

proses is carried in several steps. At the last stage the product passes

the resting tube where homogeneous structures is fixed and finally is

filled in package.

The

storage and distribution of products must be carried at temperature which

is lower than the applicaiton temperature to keep quality at the highest

level.

Please click to expand the picture

Margarine types

There are 3 classes of margarines accourding to TS 2812 Margarine

Standard:

1-Table

margarine

2-Vegetable

ghee

3-Food

industry margarine

They are also classified to salty and non salty types upon their salt

contents.

|